Sydney Structural Drafting

Structural steel detailing is a critical piece in the fabrication or structural steel manufacturing process. Failure to shape this piece with all the correct information can lead to rework lost man-hours on site or at the fabrication factory not to mention cost and scheduling of lifting machinery.

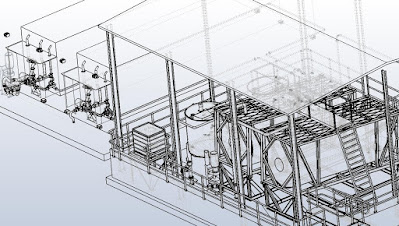

As Structural steel is the skeleton system of a building be it residential, industrial, or commercial and yet Structural steel detailing is not limited to buildings, it can be found in mining infrastructure, shipbuilding and mechanical machinery.

The process of steel detailing establishes crucial communication between all stakeholders such as engineers, architects, contractors, and fabricators. This communication ensures all components of the building or project come together seamlessly.

In relation to the steel detailing process, each professional is entrusted with specific responsibilities. The structural engineer ensures the design, strength and integrity of the erected steel structures.

The architect, on the other hand, must make sure that the structure complies with the major plan dimensions and the building codes of the location. Finally, the detailer is responsible for getting the steel detailing drawings approved by the structural engineer and the architect prior to release for fabrication.

Because of its important role in structural engineering, steel detailing requires near 100% accuracy. A tiny error in calculation or execution can set off a chain reaction of events that can cost a project’s valuable time and money. Steel detailing exists to keep each of the professionals involved in the process as focused and faithful to a building’s blueprints as possible.

Steel detailing revolves around the creation of detailed drawings to be used by fabricators and contractors. The drawings already include plans and estimates for each building, as well as other reports and tasks relevant and crucial for the successful completion of a project.

The steel detailing process includes reinforcing steel detailing, anchor setting plans, steel design, connectivity diagrams, shop bolt summary, and Bill of Material (BoM).

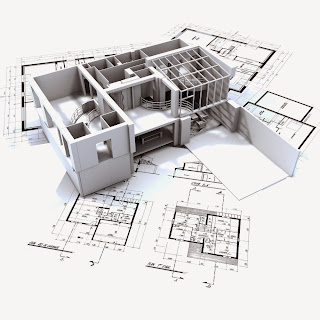

Structural Drawing

In general terms there are two types of drawings involved in structural detailing

- Detail Drawings, are highly precise and detailed drawings of each steel piece or component to be made by a steel fabricator. They are often made for columns, beams, joints, trusses, braces, and other construction material steel.

They include material specifications, component sizes and dimensions, surface specs, welding, bolting, and painting details and any other information necessary for the fabrication of each steel component. Since shop drawings are only useful for fabrication purposes, they do not include information about the erection or installation of the individual steel components.

- Erection drawings, on the other hand, display plans in dimension and locate each steel component within the overall structure. These drawings include information about the positioning of each component, their installation requirements, and the installation of other components that hold the steel component in place (bolts, wedge anchors, and welding spots, for example).

For more information on Structural Steel Detailing